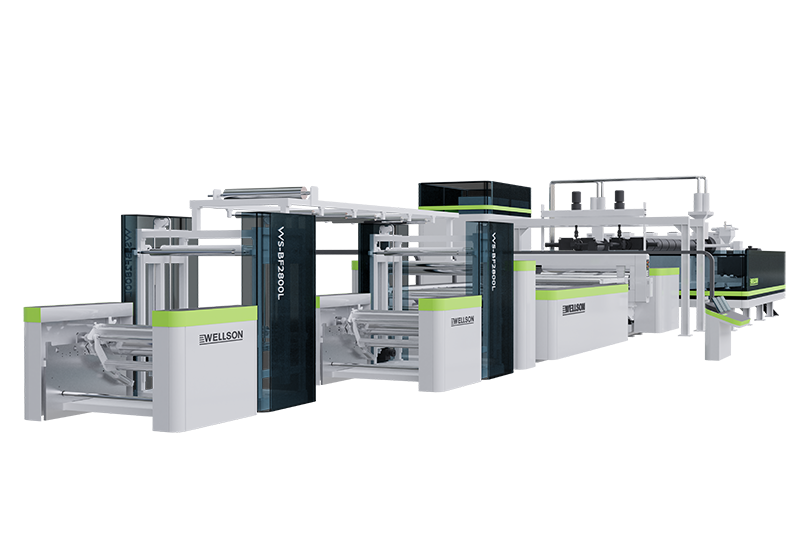

Factory wholesale Hot Melt Adhesive Laminating Machine - Woven Fabric Extrusion Coating and Laminating Line – Wellson

Factory wholesale Hot Melt Adhesive Laminating Machine - Woven Fabric Extrusion Coating and Laminating Line – Wellson Detail:

*INTRODUCTION

Woven fabric extrusion coating line is equipped with high-performance extruder, chrome-plated chill roll, and high tension control system. The extruders coat PE polymer resins onto a substrate of woven fabric and make the high bonding strength between melt curtain and woven fabric substrate.

The line can also be equipped with up to 4 extruders, to make sandwich or tubular coating. We are able to add some proper pre-treatment such as pre-heating and pre-hydration before coating. Some other unique line solution is available to best meet your market need.

A large portion of woven sacks is produced with coating, because coated sacks provide much better protection of the contents from dust and especially from moisture. Coated fabric also offers better printability. For Coating thin layer of LDPE / PP / EVA on substrates like Woven Sacks, Tarpaulins, Jumbo Bags, BOPP Film, Paper, Aluminum Foil, Polyester Film, Cotton Fabrics, Jute, Non Woven Fabrics, etc. Tandem Lamination Line for coating tube Woven Fabrics, to produce multi-layer laminates along with the various substrates like Paper, Aluminum Foil, Polyester film etc. Extrusion Coating Lamination Machine adds superior protection for products when they are packed. Extrusion coating lamination plant is a suitable solution to produce very slim lining layers made of PP, LDPE. This coating material will them be added to packaging components like woven sacks, giant size bags, aluminum foil, cotton and jute fabric bags, etc.

*Machine Details

Product width: any option from 1000mm to 3500mm, upon request

Coating Resin: LDPE, LLDPE, EVA

Substrates: woven fabric

Diameter of Unwinding: Φ1200mm max.

Diameter of Winding: Φ 1000mm max.

*Application

Some typical application of woven coating / laminating will be car mat, bulk bag, water drainage pipe, tarpaulins, tents and etc.

Product detail pictures:

Related Product Guide:

Cooperation

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Factory wholesale Hot Melt Adhesive Laminating Machine - Woven Fabric Extrusion Coating and Laminating Line – Wellson , The product will supply to all over the world, such as: Argentina, Mauritania, moldova, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.