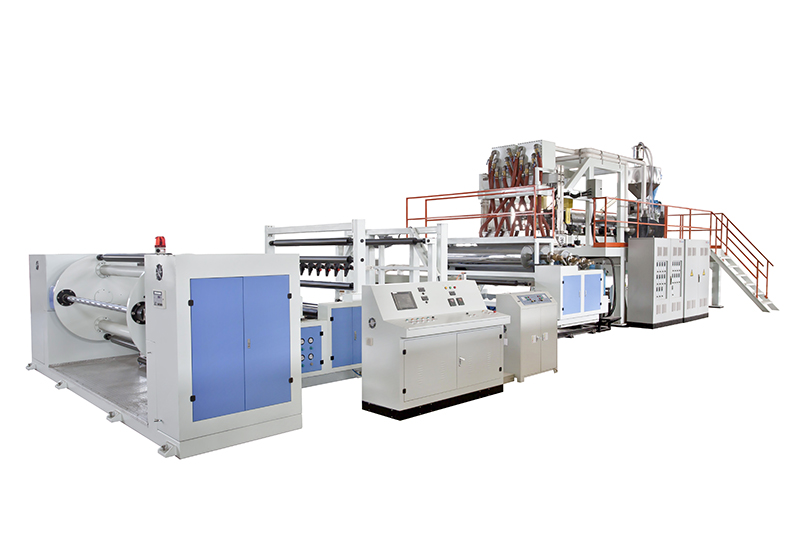

Factory source Extrusion Laminating Line - EVA / POE Solar Panel Encapsulation Film Extrusion Line – Wellson

Factory source Extrusion Laminating Line - EVA / POE Solar Panel Encapsulation Film Extrusion Line – Wellson Detail:

*INTRODUCTION

Solar panel encapsulation film extrusion line takes EVA and POE as raw materials. The process includes materials handling, heating, extruding, calendaring, cooling and winding. The production line can be specially made by customer’s requirements. The film product is a new type of thermosetting hot melt film, anti-adhesive at normal temperature, easy for operation. It is fully shaped and adhesive after heating and laminating. It can make the silicon wafer, glass, backplane multi-layer material firmly bonded into the whole one. Excellent heat and humidity resistance, UV resistance, fully realize the long-term use of solar modules in outdoor requirements.

EVA film has the advantages of environmental protection, long-term UV resistance, no yellowing, high light transmission, strong adhesion, aging resistance and low thermal shrinkage. This product is mainly used for the encapsulation of solar cell modules. After lamination and curing, it is bonded and sealed. It has the functions of high light transmittance for cell modules, preventing water vapor penetration, high and low temperature resistance, and anti-ultraviolet light, so as to ensure the stable and efficient use of cell modules. , is a novel and reliable packaging material.

POE polyolefin elastomer (Polyolefin elastomer) has the general characteristics of thermoplastic elastomer, but also has excellent toughness and good process ability. The product features are as follows: 1) The product has excellent heat resistance and cold resistance, and has a wide range of operating temperatures; 2) It has good weather resistance and aging resistance. Because there is no unsaturated double bond in the molecular structure of POE plastic, it has excellent aging resistance; 3) Oil resistance, compression set resistance and wear resistance are not very good; 4) POE plastics have narrow molecular weight distribution, good fluidity, and good compatibility with polyolefin; 5) Good fluidity can improve fillers The dispersion effect of the product can also improve the weld line strength of the product.

*Application

1) EVA solar panel encapsulation: used for solar panel encapsulation. Non-sticky at room temperature, easy to handle. The curing and bonding reactions are produced by hot pressing, resulting in a permanent adhesive seal.

2) EVA glass interlayer film: used for interior decorative glass interlayer.

3) POE solar panel packaging: used for solar panel packaging.

*Technical Data

| Model No | Die Width | Film Width | Film Weight | Line Speed |

| WS160/180-2650 | 2650mm | 2400mm | 0.3-1.0mm | 15m/min |

| WS180/180-3000 | 3000mm | 2750mm | 0.3-1.0mm | 15m/min |

| WS200/200-3000 | 3000mm | 2750mm | 0.3-1.0mm | 15m/min |

Remarks: Other sizes of machines are available upon request.

*Features/Advantages

1) Excellent mixing and plasticizing effect of extruder

2) Eliminate thermal stress and solve the problem of thermal shrinkage

3) Unique design to solve the problem of sticky layer and peeling of adhesive film

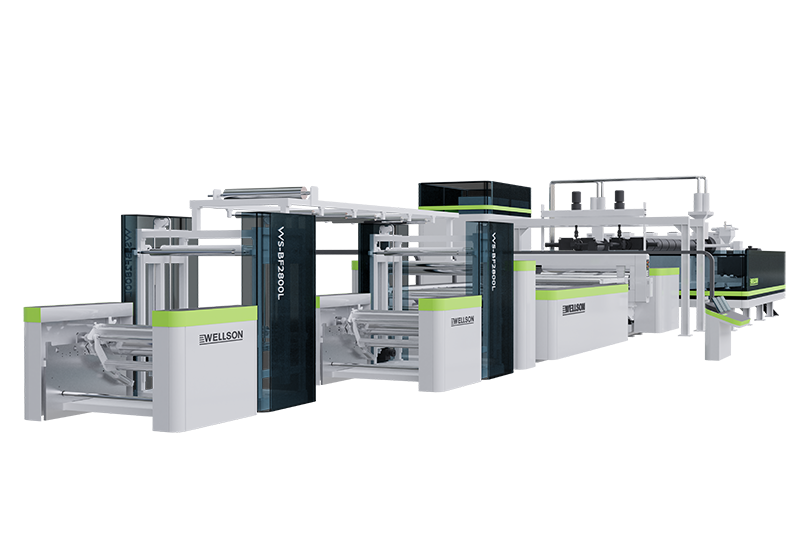

Product detail pictures:

Related Product Guide:

Cooperation

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Factory source Extrusion Laminating Line - EVA / POE Solar Panel Encapsulation Film Extrusion Line – Wellson , The product will supply to all over the world, such as: US, Brunei, Accra, With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.