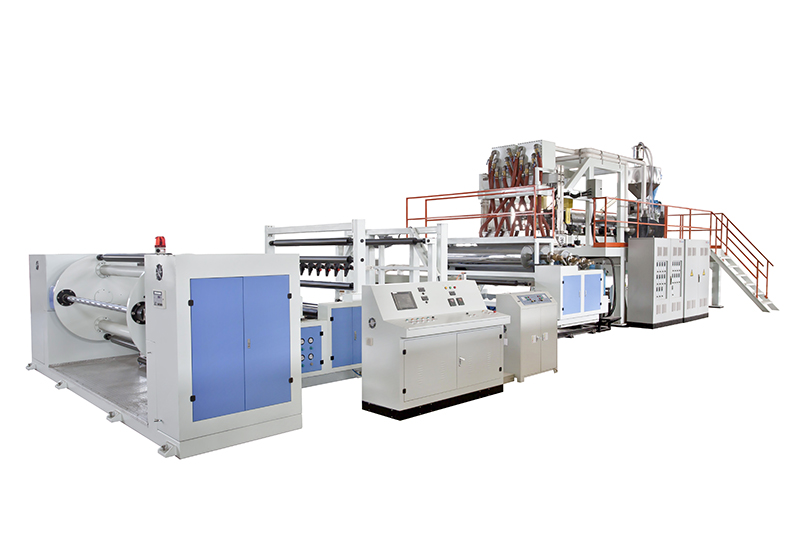

factory customized Peva Cast Film Extrusion Machine - Multi-layer Co-extrusion CPP Cast Film Line – Wellson

factory customized Peva Cast Film Extrusion Machine - Multi-layer Co-extrusion CPP Cast Film Line – Wellson Detail:

*INTRODUCTION

CPP cast film line is used to produces high-quality cast polypropylene film (CPP film) for a wide range of packaging applications. Equipped with auto thickness controlling system and efficient chill roll, the line produces CPP film of high transparency and very low gauge variation, ideal for laminating and metalizing. The 3-layer CPP film is most welcome in the market.

We offers a wide variety of configurations for CPP film machine in regard to extruder quantity, film width, flat die and other downstream equipment. 3-layer co-extrusion configuration are most popular in the market. The screws are optimal designs for PP polymer processing. The whole line is highly integrated in the PLC control system and operated on HMI. Our know-how and experiences of cast film equipment enable us to provide a reliable and high performance CPP film line for customers worldwide.

*APPLICATION

Wide packaging application for processed food and bakery products, cosmetics, pharmaceutical,

bakery, confectionery, stationery, apparel, DVD case and flower; lamination grade CPP film used as a heat seal layer along with BOPP or polyester film in a laminate for packing the articles; metalized grade CPP film with co-polymer and homo-polymer to meet the specialized needs for the packaging of various products.

CPP film are the most well-known packaging film in the market. CPP film is low density film with excellent tear and impact resistance properties as well as excellent transparency. It is perfect for food packaging from bread to candies. For some industry and technical film, cast polypropylene (CPP) film is used to laminate with BOPET or BOPA film to acquire excellent mechanical and optical properties. CPP film have some outstanding features such as high clarity, glossiness, moisture barrier and high sealing performance, which are best option for packing food.

*TECHNICAL DATA

|

Model No. |

Screw Dia. |

Die Width |

Film Width |

Film Thickness |

Line Speed |

| FMC65/110/65-2000 | Ф65mm/Ф110mm/Ф65mm | 2000mm | 1600mm | 0.02-0.15mm | 250m/min |

| FMC65/125/65-2400 | Ф65mm/Ф125mm/Ф65mm | 2400mm | 2000mm | 0.02-0.15mm | 250m/min |

| FMC90/135/90-2900 | Ф90mm/Ф135mm/Ф90mm | 2900mm | 2500mm | 0.02-0.15mm | 250m/min |

Remarks: Other sizes of machines are available upon request.

*FEATURES & ADVANTAGES

1) Options for up to 5-layers co-extruded film structure

2) Option for up to 4000mm film net width

3) Air knife and high performance chill roller

4) Automatic film thickness controlling

5) In-line edge trim and recycling

6) Auto film winding

Product detail pictures:

Related Product Guide:

Cooperation

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for factory customized Peva Cast Film Extrusion Machine - Multi-layer Co-extrusion CPP Cast Film Line – Wellson , The product will supply to all over the world, such as: Saudi Arabia, Poland, Hungary, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.