8 Year Exporter Hotmelt Glue Laminator - EVA / PEVA Cast Film Extrusion Line – Wellson

8 Year Exporter Hotmelt Glue Laminator - EVA / PEVA Cast Film Extrusion Line – Wellson Detail:

*INTRODUCTION

The line is well designed to produce EVA and PEVA films for various applications. The most optimized design of extruder and T die guarantees high-performance extrusion and various levels of features and automation are available to best meet your needs. The line use EVA resin as raw materials to produce EVA film. It also accepts the combination of different resin materials such as EVA, LDPE, LLDPE, and HDPE to combine their unique properties. Our cast film machine for EVA / PEVA film are specially designed for those thermoplastic polymer. The processing of EVA film and PEVA film has quite different requirements on screws, flow channels and guiding rollers. Every details of our cast film machine take all those requirements into considerations for best quality.

Ethylene vinyl acetate or EVA is a copolymer of ethylene and vinyl acetate. It is an extremely elastic and tough thermoplastic of excellent clarity and gloss with little odor. EVA has good flex crack and puncture resistance, is relatively inert, adheres well to many substrates and is heat sealable which makes its use in film applications especially attractive.

*APPLICATION

EVA film can be used as solar battery encapsulation, or adhesive film for glass lamination.

PEVA film products has various applications for shower curtain, gloves, umbrella cloth, table cloth, rain coat etc.

This thermoplastic resin is copolymerized with other resins like LDPE and LLDPE or it is part of a multilayer film. In blends and copolymers, the percentage of EVA ranges from 2% to 25%. It enhances clarity and sealability of olefins (LDPE/LLDPE) whereas a higher percentage of EVA is often used to reduce the melting point. It also improves the low temperature performance. In general, the mechanical properties will depend on the vinyl acetate content; the higher its percentage is, the lower is the barrier to gas and moisture and the better the clarity.

EVA is only an average barrier to gases and moisture, which makes it not a good choice for food packaging applications and, therefore, has been replaced by metallocene PE in many of these applications. mPE also offers faster hot tack, and has better down-gauging properties, which allows for thinner films and packaging. Nevertheless, EVA remains an important packaging material and demand will remain strong particularly for non-food applications.

*TECHNICAL DATA

| Model No. | Screw Dia. | Die Width | Film Width | Film Thickness | Line Speed |

| FME120-1900 | ¢120mm | 1900mm | 1600mm | 0.02-0.15mm | 180m/min |

| FME135-2300 | ¢135mm | 2300mm | 2000mm | 0.02-0.15mm | 180m/min |

| FME150-2800 | ¢150mm | 2800mm | 2500mm | 0.02-0.15mm | 180m/min |

Remarks: Other sizes of machines are available upon request.

*FEATURES & ADVANTAGES

1) Any film width (up to 4000mm) at customer’s disposable.

2) Very low variation of film thickness

3) In-line film edge trim and recycling

4) In-line extrusion coating is optional

5) Auto film winder with different size of air shaft

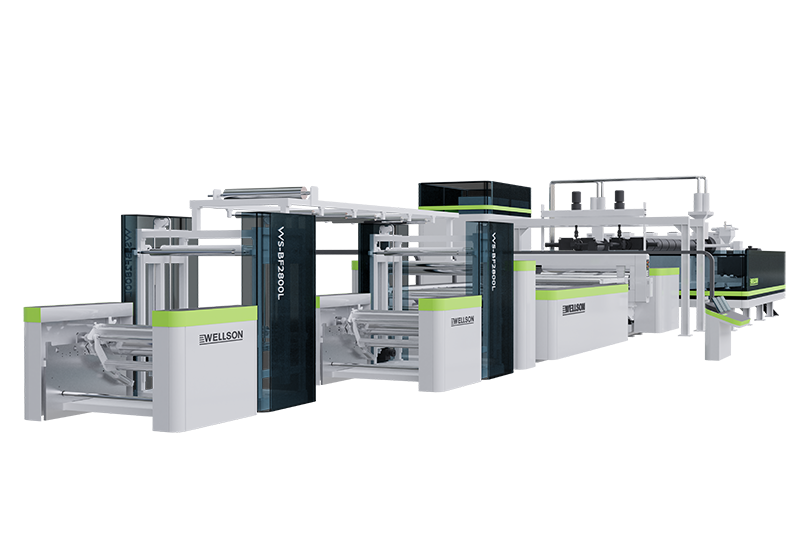

Product detail pictures:

Related Product Guide:

Cooperation

Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for 8 Year Exporter Hotmelt Glue Laminator - EVA / PEVA Cast Film Extrusion Line – Wellson , The product will supply to all over the world, such as: Ecuador, Lithuania, New York, At Present, our products have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.